-

FG Series High Precision & Direct Pressure Injection Molding Machine(80-250T)

Technical parameters | Feature | Feature

-

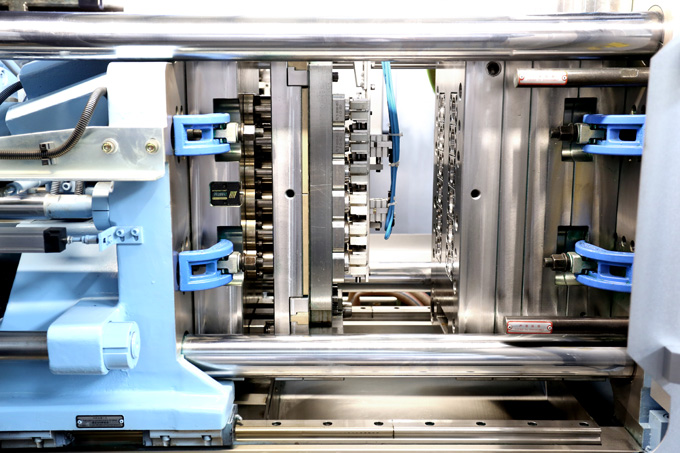

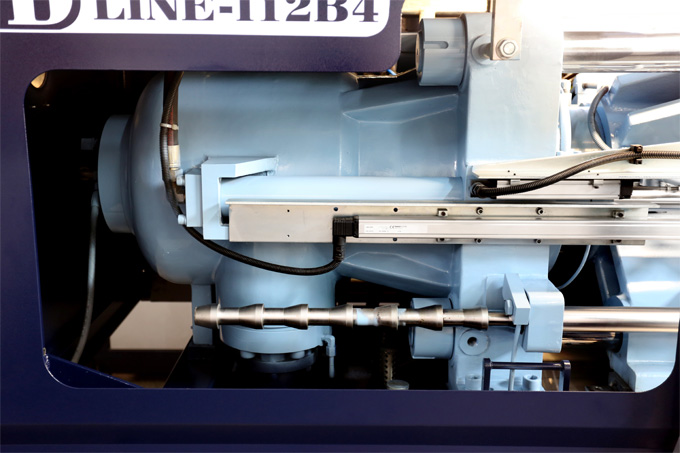

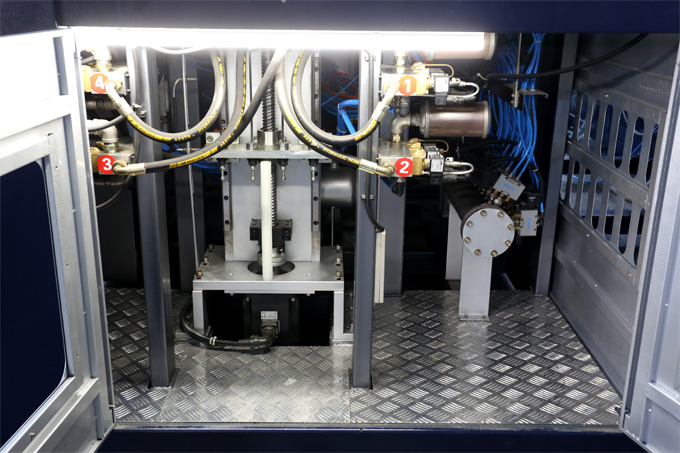

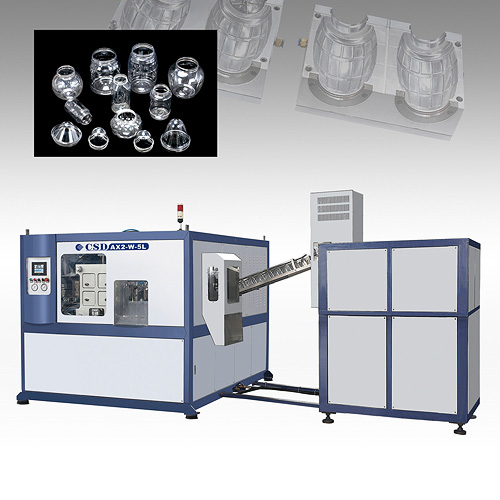

CSD-LINE-L12B4 Injection Molding Machine

Technical parameters | Feature | Feature

-

CSD-PET-DP Series High Precision,High Capacity Direct Pressure PET Production Line

Technical parameters | Feature | Feature

-

CSD-RP 10-20 Cavity High Precision High-speed Rotary Blowing Machine

Technical parameters | Feature | Feature

-

CSD-PET-DP Series High Precision,High Capacity Direct Pressure PET Production Line

Technical parameters | Feature | Feature

-

CSD-550S/X1-20L Injection Molding Machine

Technical parameters | Feature | Feature

-

FG Series High Precision & Direct Pressure Injection Molding Machine(80-250T)

Technical parameters | Feature | Feature

-

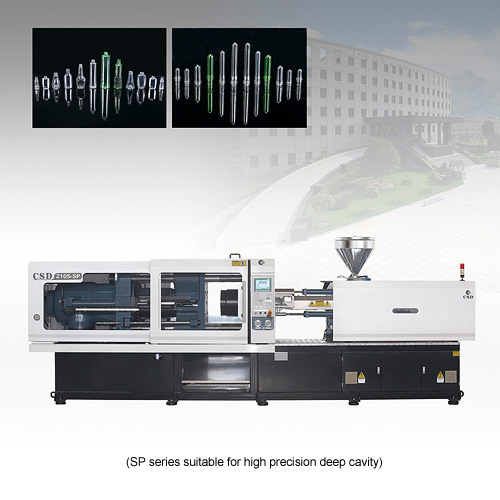

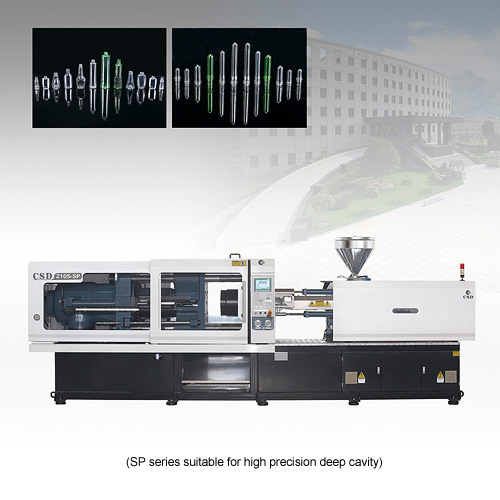

SP Series High Precision & Direct Pressure Injection Molding Machine(80-250T)

Technical parameters | Feature | Feature

-

P Series Injection Molding Machine(150-680T)

Technical parameters | Feature | Feature

-

W-S Series Injection Molding Machine(100T-280T)

Technical parameters | Feature | Feature

-

W-S Series Injection Molding Machine(350T-1200T)

Technical parameters | Feature | Feature

-

S Series Injection Molding Machine(260T-320T)

Technical parameters | Feature | Feature

-

CSD-RP 10-20 Cavity High Precision High-speed Rotary Blowing Machine

Technical parameters | Feature | Feature

-

AB Up Blow Series Automatic Blow Molding Machine(2 Cavity,4 Cavity,Maximum Capacity:2 Liter)

Technical parameters | Feature | Feature

-

AB Up Blow Series Automatic Blow Molding Machine(6 Cavity,8 Cavity,Maximum Capacity:1.5 Liter)

Technical parameters | Feature | Feature

-

PET Two-Stage Automatic Linear High-Speed Blow Molding Machine(10 Cavity,12 Cavity,Maximum Capacity:1.5 Liter)

Technical parameters | Feature | Feature

-

PET Two-Stage Linear High-Speed Automatic Blow Molding Machine

Technical parameters | Feature | Feature

-

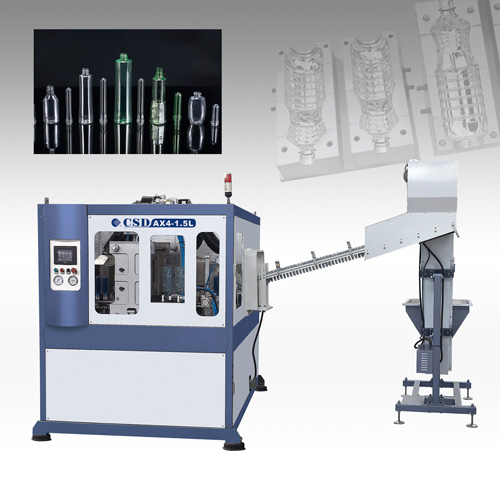

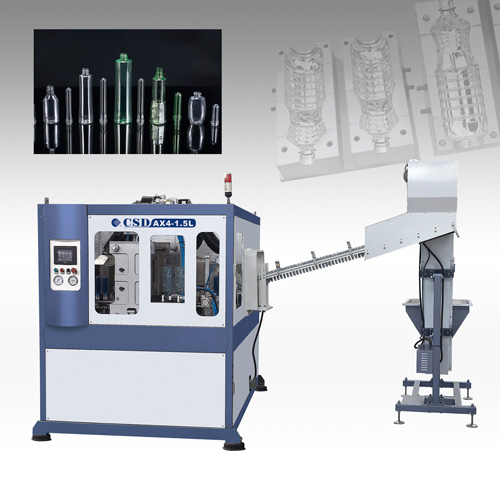

AX Down Blow Series Automatic Blow Molding Machine(1,2,3,4,6 Cavity,Maximum Capacity:1.5 Liter)

Technical parameters | Feature | Feature

-

1 Cavity Manual Preform Feeding Maximum Capacity:2Liter Long message 2/3 ter

Technical parameters | Feature | Feature

-

AX Down Blow Series Automatic Blow Molding Machine(1,2,3,4,6 Cavity,Maximum Capacity: 1.5 Liter)

Technical parameters | Feature | Feature

-

AX Down Blow Series Automatic Blow Molding Machine(1 Cavity,2 Cavity,Maximum Capacity:5 Liter)

Technical parameters | Feature | Feature

-

1 Cavity Manual Preform Message 3/3 form Feeding.Maximum Capacity:5 Liter

Technical parameters | Feature | Feature

-

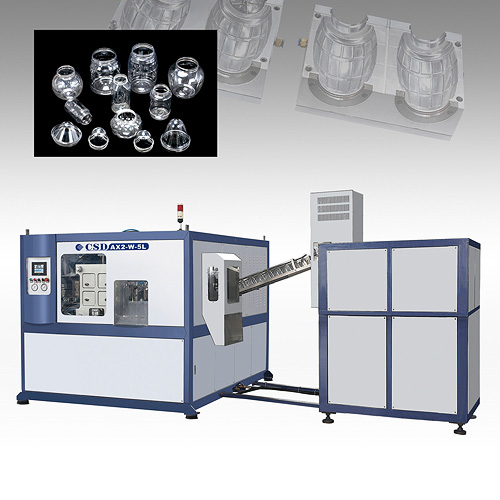

AX Down Blow Series Automatic Blow Molding Machine(1 Cavity,2 Cavity,Wide Mouth Jar, Maximum Capacity:5 Liter)

Technical parameters | Feature | Feature

-

Semi-Automatic Blow Molding Machine

Technical parameters | Feature | Feature

-

Semi-automatic Blow Molding Machine

Technical parameters | Feature | Feature

-

Semi-Automatic Blow Molding Machine

Technical parameters | Feature | Feature

-

PET 5-Gallon Automatic Blow Molding Machine(1 Cavity,Preform Feeding by Hand)

Technical parameters | Feature | Feature

-

PET 5-Gallon Semi-Automatic Blow Molding Machine(1 Cavity)

Technical parameters | Feature | Feature

-

PC 5-Gallon Blow Molding Machine(1 Cavity)

Technical parameters | Feature | Feature

-

EB Series Extrusion Blow Molding Machine(Double Station,Multi-heads,Screw Diameter:45mm,55mm,65mm,75mm)

Technical parameters | Feature | Feature

-

EBS Servo Drive Series Extrusion Blow Molding Machine(Double Station,Multi-heads,Screw Diameter:50mm,60mm,70mm,80mm)

Technical parameters | Feature | Feature

-

EB Series Extrusion Blow Molding Machine(Double Station,Multi-heads,Screw Diameter:80mm,90mm,100mm)

Technical parameters | Feature | Feature

-

EB Series Extrusion Blow Molding Machine(Single Station,Screw Diameter:90mm,100mm)

Technical parameters | Feature | Feature

-

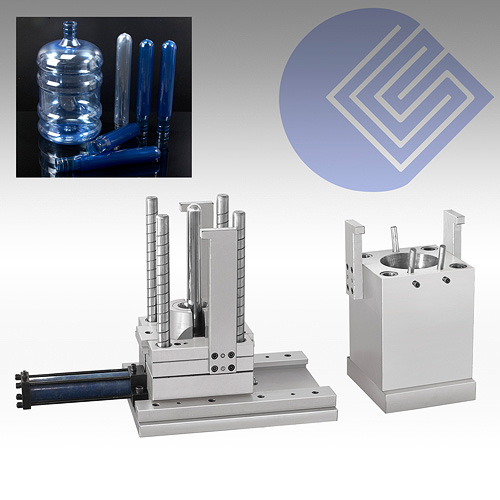

Preform Mould With Hot Runner Valve Gate

Technical parameters | Feature | Feature

-

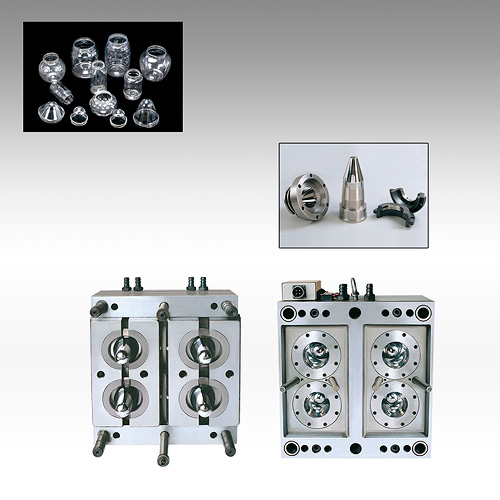

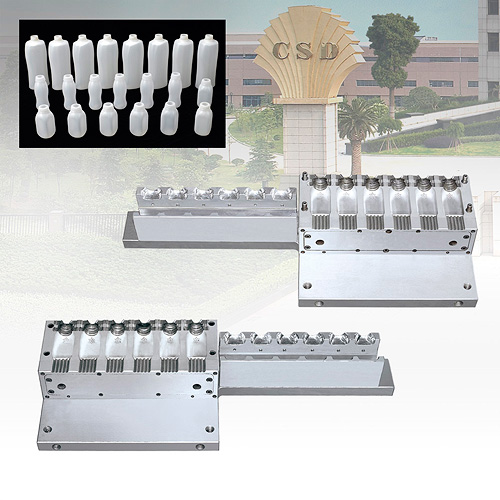

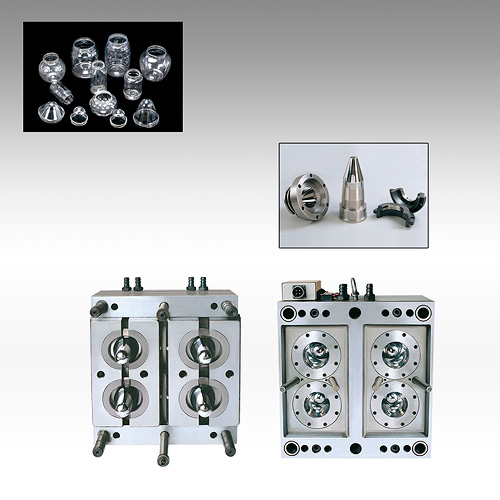

Jar Preform Mould

Technical parameters | Feature | Feature

-

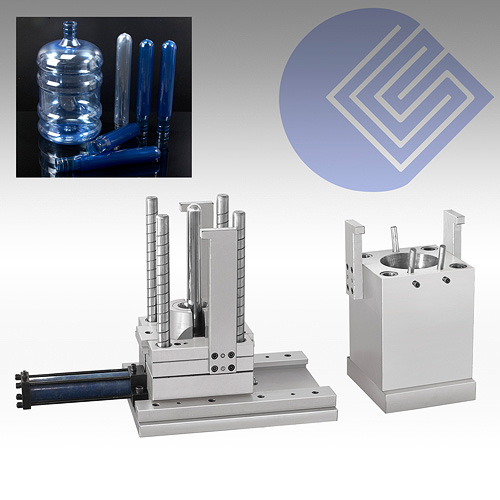

1 Cavity 5 Gallon Preform Mould

Technical parameters | Feature | Feature

-

Anti-proof Cap Mould with Hot Runner

Technical parameters | Feature | Feature

-

Blow Mould for PET Bottle(6 Cavity)

Technical parameters | Feature | Feature

-

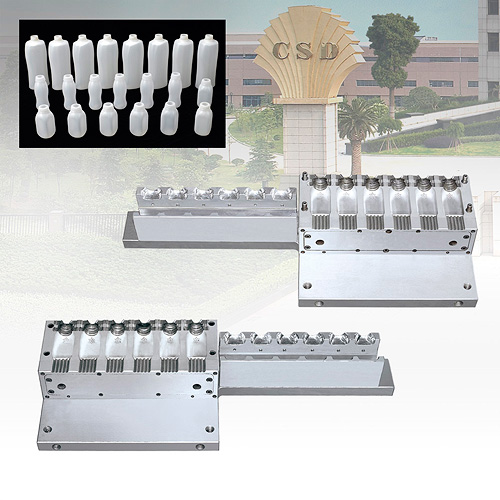

Blow Mould for Extrusion Blow Molding Machine(6 Cavity)

Technical parameters | Feature | Feature

-

PC 5-Gallon Blow Mould

Technical parameters | Feature | Feature

-

Blow Mould for Extrusion Blow Molding Machine(2 Cavity)

Technical parameters | Feature | Feature

-

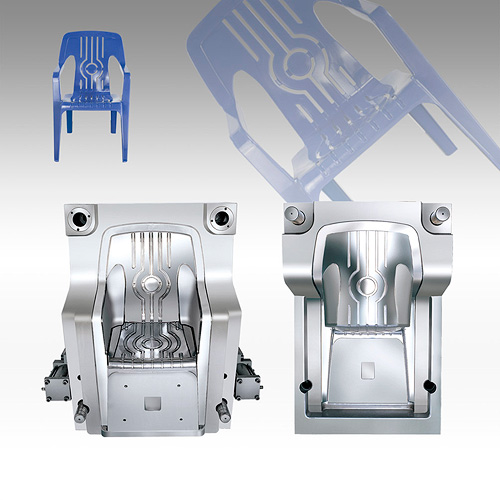

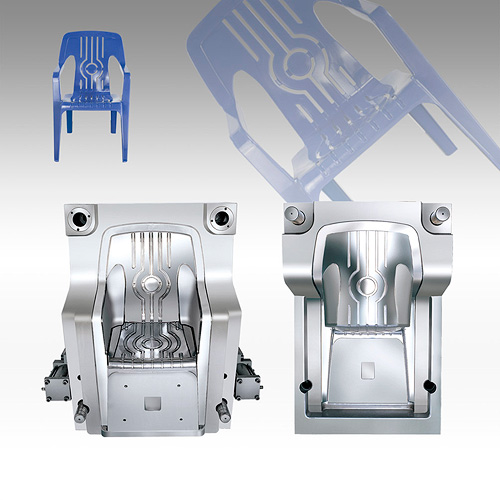

Plastic Chair Mould

Technical parameters | Feature | Feature

-

Blow Mould for PET Bottle(1 Cavity)

Technical parameters | Feature | Feature

-

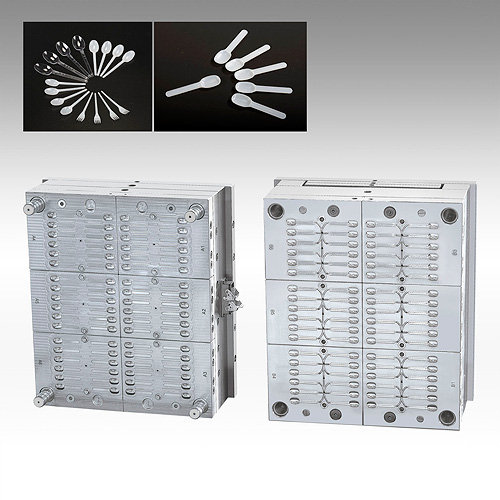

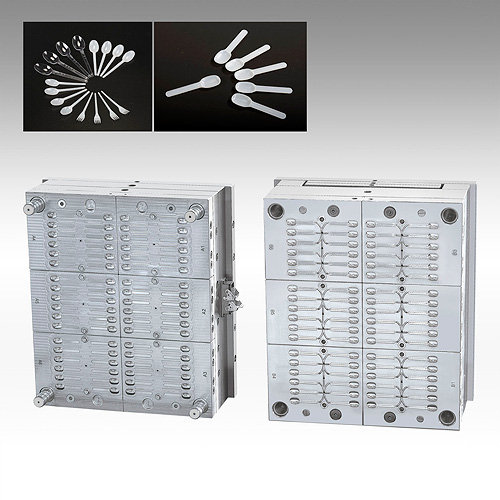

Cutlery Mould(72 cavity)

Technical parameters | Feature | Feature

-

Thin-wall products mould

Technical parameters | Feature | Feature

-

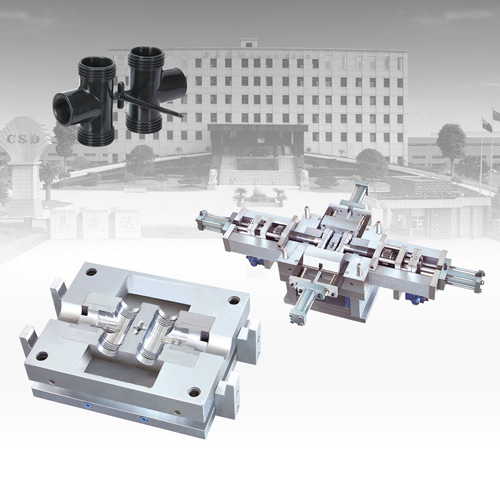

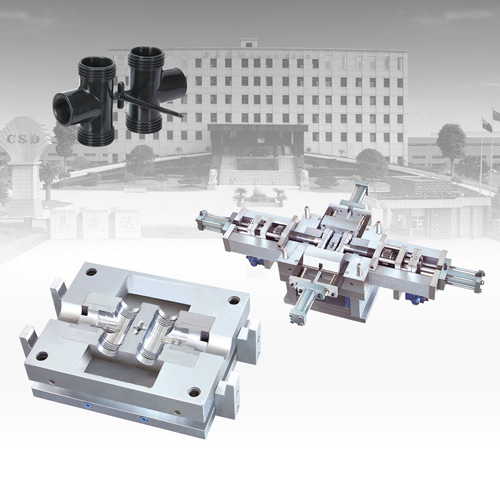

Pipe Fitting Mould

Technical parameters | Feature | Feature

-

Daily Necessities Mould

Technical parameters | Feature | Feature

-

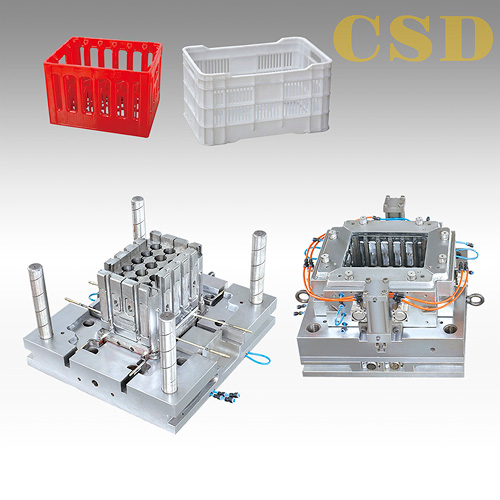

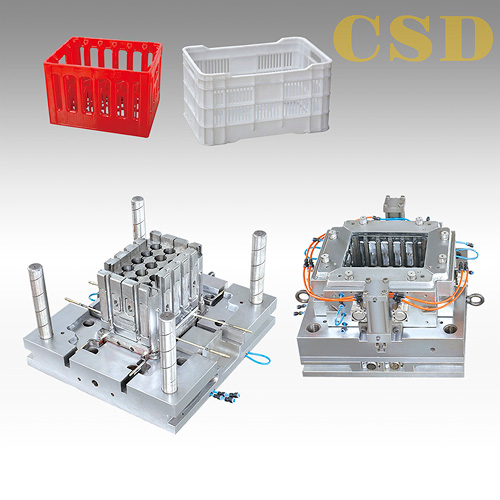

Crate Mould

Technical parameters | Feature | Feature

-

Daily Necessities Mould

Technical parameters | Feature | Feature

-

Blow Mould For 5GL PET bottle

Technical parameters | Feature | Feature

-

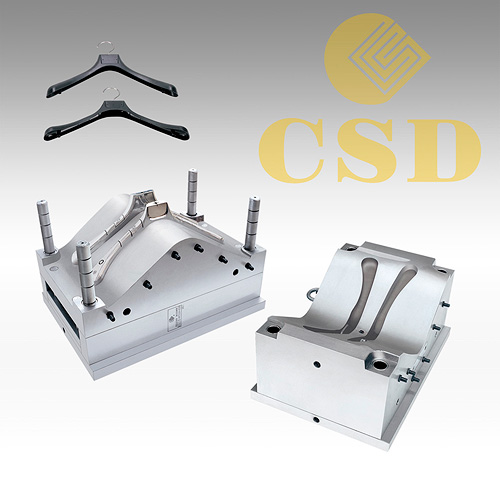

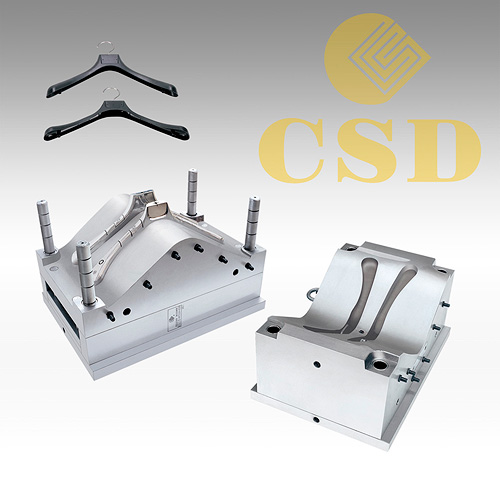

Hanger Mould

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

Technical parameters | Feature | Feature

Technical parameters | Feature | Feature

-

Technical parameters | Feature | Feature

Technical parameters | Feature | Feature

|

|

PRODUCTS PRODUCTS

|

You are here: Home - Products - New Arrival |

|

| |

|

| Product Name: CSD-LINE-L12B4 Injection Molding Machine |

-

1.The imported servo motor closes the mould and runs smoothly.

2.The clamping force of the balanced elbow bar of the crank arm is greater.

3.Layered far-infrared heating, temperature control, heating lamp tube and bottle blank distance can be moved individually and arbitrarily, so that the bottle blank is uniformly heated, easy to blow molding.

4.The man-machine interface of color liquid crystal can store various technological conditions of container forming. All parameters in the process of machine operation can be adjusted on touch screen without mechanical adjustment.

5.Because the main components are designed and manufactured optimally and the process units in the production process are easy to connect, the operation and maintenance of the machine are very easy and fast.

-

|

Name of main fittings |

Brand |

Origin |

|

Servo motor |

Taida |

China Taiwan |

|

Combination Valve |

Parker |

U.S.A |

|

Cylinder |

Festo |

Germany |

|

Controller |

Taida |

China Taiwan |

|

PLC |

Taida /Siemens |

China Taiwan / Germany |

|

Solenoid valve |

Festo |

Germany |

|

|

|