-

FG Series High Precision & Direct Pressure Injection Molding Machine(80-250T)

Technical parameters | Feature | Feature

-

CSD-LINE-L12B4 Injection Molding Machine

Technical parameters | Feature | Feature

-

CSD-PET-DP Series High Precision,High Capacity Direct Pressure PET Production Line

Technical parameters | Feature | Feature

-

CSD-RP 10-20 Cavity High Precision High-speed Rotary Blowing Machine

Technical parameters | Feature | Feature

-

CSD-PET-DP Series High Precision,High Capacity Direct Pressure PET Production Line

Technical parameters | Feature | Feature

-

CSD-550S/X1-20L Injection Molding Machine

Technical parameters | Feature | Feature

-

FG Series High Precision & Direct Pressure Injection Molding Machine(80-250T)

Technical parameters | Feature | Feature

-

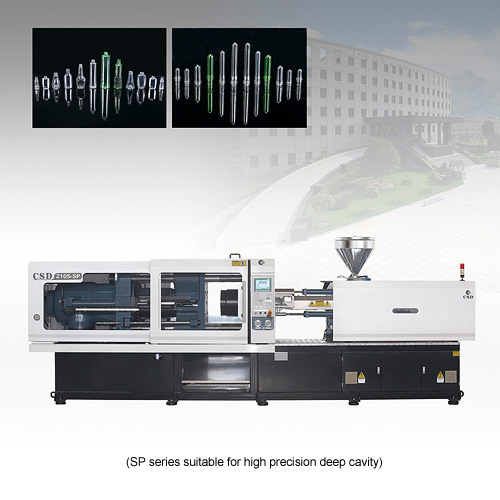

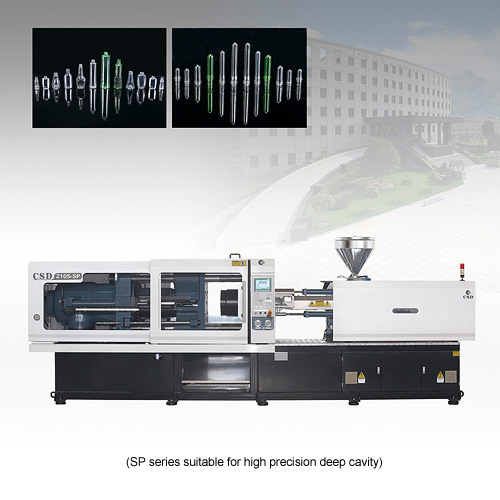

SP Series High Precision & Direct Pressure Injection Molding Machine(80-250T)

Technical parameters | Feature | Feature

-

P Series Injection Molding Machine(150-680T)

Technical parameters | Feature | Feature

-

W-S Series Injection Molding Machine(100T-280T)

Technical parameters | Feature | Feature

-

W-S Series Injection Molding Machine(350T-1200T)

Technical parameters | Feature | Feature

-

S Series Injection Molding Machine(260T-320T)

Technical parameters | Feature | Feature

-

CSD-RP 10-20 Cavity High Precision High-speed Rotary Blowing Machine

Technical parameters | Feature | Feature

-

AB Up Blow Series Automatic Blow Molding Machine(2 Cavity,4 Cavity,Maximum Capacity:2 Liter)

Technical parameters | Feature | Feature

-

AB Up Blow Series Automatic Blow Molding Machine(6 Cavity,8 Cavity,Maximum Capacity:1.5 Liter)

Technical parameters | Feature | Feature

-

PET Two-Stage Automatic Linear High-Speed Blow Molding Machine(10 Cavity,12 Cavity,Maximum Capacity:1.5 Liter)

Technical parameters | Feature | Feature

-

PET Two-Stage Linear High-Speed Automatic Blow Molding Machine

Technical parameters | Feature | Feature

-

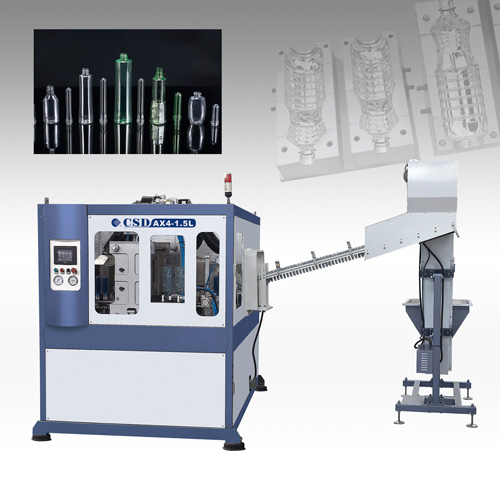

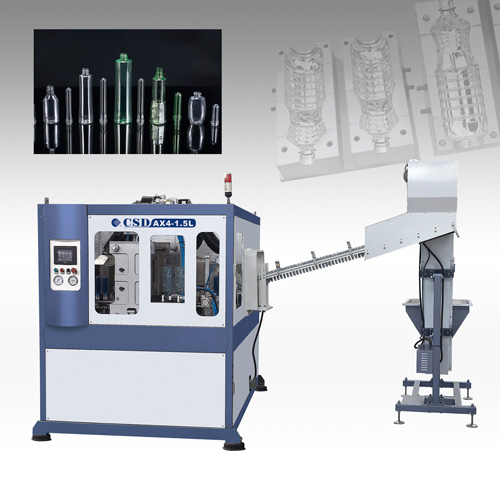

AX Down Blow Series Automatic Blow Molding Machine(1,2,3,4,6 Cavity,Maximum Capacity:1.5 Liter)

Technical parameters | Feature | Feature

-

1 Cavity Manual Preform Feeding Maximum Capacity:2Liter Long message 2/3 ter

Technical parameters | Feature | Feature

-

AX Down Blow Series Automatic Blow Molding Machine(1,2,3,4,6 Cavity,Maximum Capacity: 1.5 Liter)

Technical parameters | Feature | Feature

-

AX Down Blow Series Automatic Blow Molding Machine(1 Cavity,2 Cavity,Maximum Capacity:5 Liter)

Technical parameters | Feature | Feature

-

1 Cavity Manual Preform Message 3/3 form Feeding.Maximum Capacity:5 Liter

Technical parameters | Feature | Feature

-

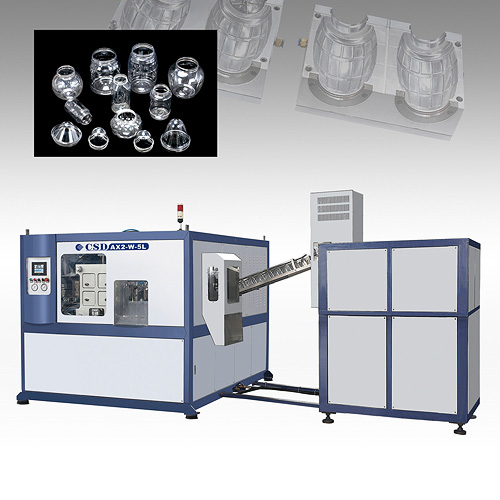

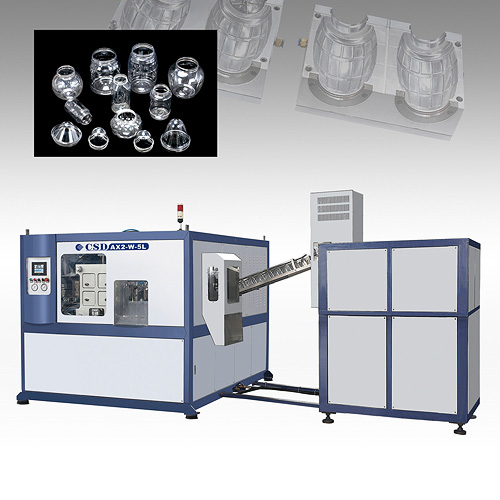

AX Down Blow Series Automatic Blow Molding Machine(1 Cavity,2 Cavity,Wide Mouth Jar, Maximum Capacity:5 Liter)

Technical parameters | Feature | Feature

-

Semi-Automatic Blow Molding Machine

Technical parameters | Feature | Feature

-

Semi-automatic Blow Molding Machine

Technical parameters | Feature | Feature

-

Semi-Automatic Blow Molding Machine

Technical parameters | Feature | Feature

-

PET 5-Gallon Automatic Blow Molding Machine(1 Cavity,Preform Feeding by Hand)

Technical parameters | Feature | Feature

-

PET 5-Gallon Semi-Automatic Blow Molding Machine(1 Cavity)

Technical parameters | Feature | Feature

-

PC 5-Gallon Blow Molding Machine(1 Cavity)

Technical parameters | Feature | Feature

-

EB Series Extrusion Blow Molding Machine(Double Station,Multi-heads,Screw Diameter:45mm,55mm,65mm,75mm)

Technical parameters | Feature | Feature

-

EBS Servo Drive Series Extrusion Blow Molding Machine(Double Station,Multi-heads,Screw Diameter:50mm,60mm,70mm,80mm)

Technical parameters | Feature | Feature

-

EB Series Extrusion Blow Molding Machine(Double Station,Multi-heads,Screw Diameter:80mm,90mm,100mm)

Technical parameters | Feature | Feature

-

EB Series Extrusion Blow Molding Machine(Single Station,Screw Diameter:90mm,100mm)

Technical parameters | Feature | Feature

-

Preform Mould With Hot Runner Valve Gate

Technical parameters | Feature | Feature

-

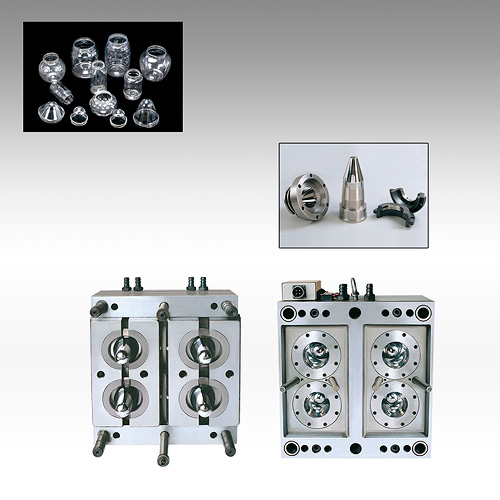

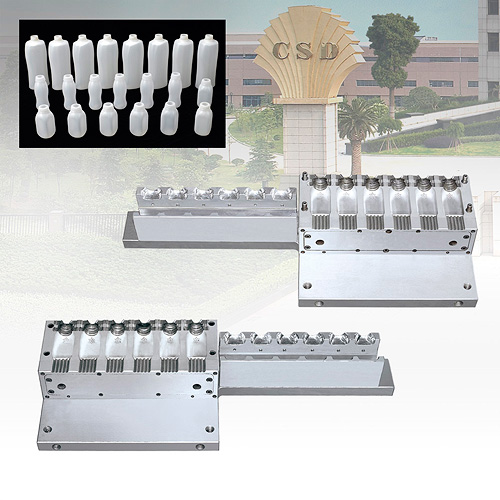

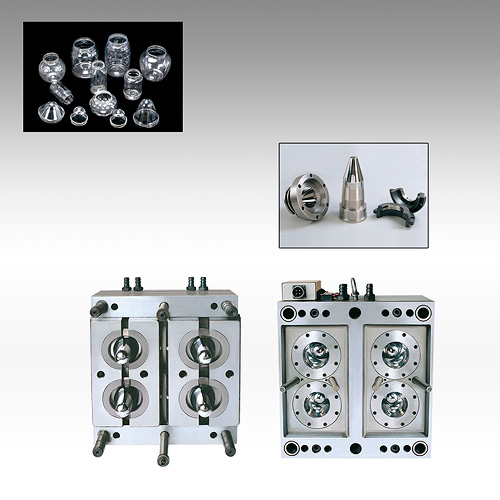

Jar Preform Mould

Technical parameters | Feature | Feature

-

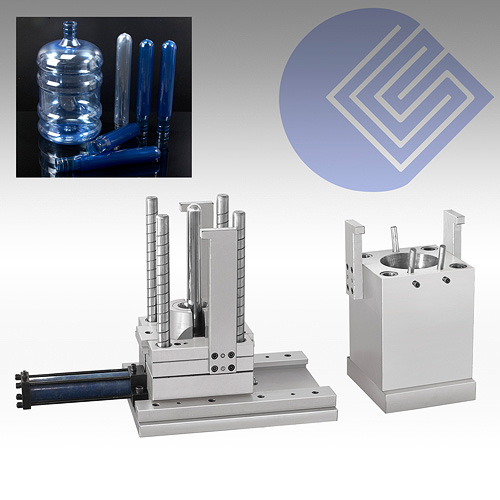

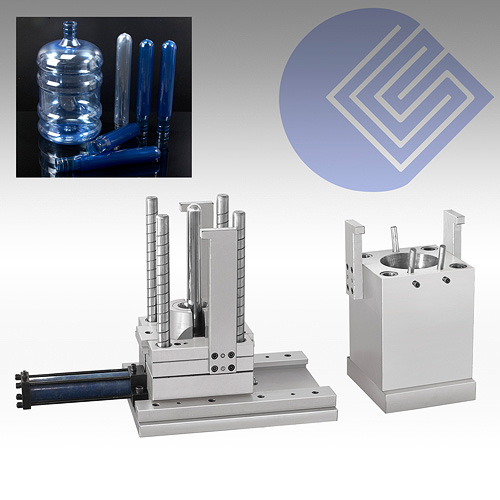

1 Cavity 5 Gallon Preform Mould

Technical parameters | Feature | Feature

-

Anti-proof Cap Mould with Hot Runner

Technical parameters | Feature | Feature

-

Blow Mould for PET Bottle(6 Cavity)

Technical parameters | Feature | Feature

-

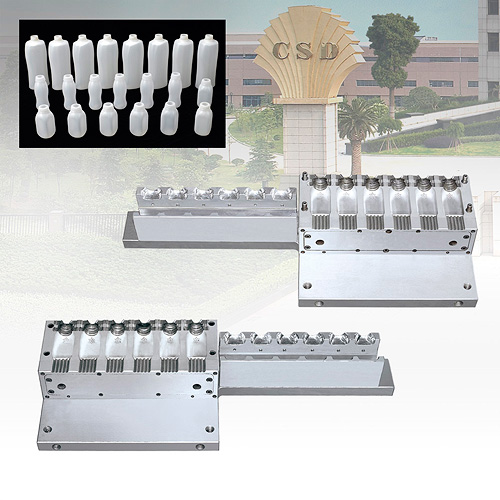

Blow Mould for Extrusion Blow Molding Machine(6 Cavity)

Technical parameters | Feature | Feature

-

PC 5-Gallon Blow Mould

Technical parameters | Feature | Feature

-

Blow Mould for Extrusion Blow Molding Machine(2 Cavity)

Technical parameters | Feature | Feature

-

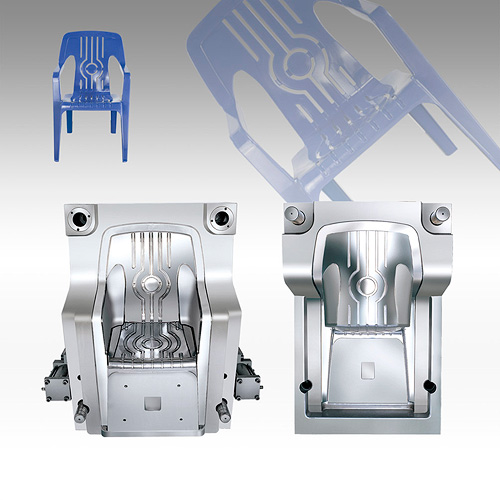

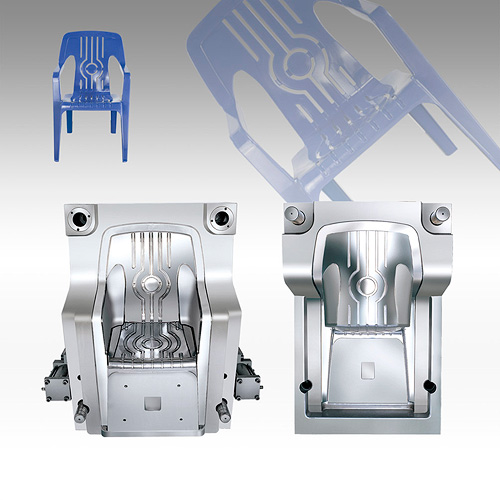

Plastic Chair Mould

Technical parameters | Feature | Feature

-

Blow Mould for PET Bottle(1 Cavity)

Technical parameters | Feature | Feature

-

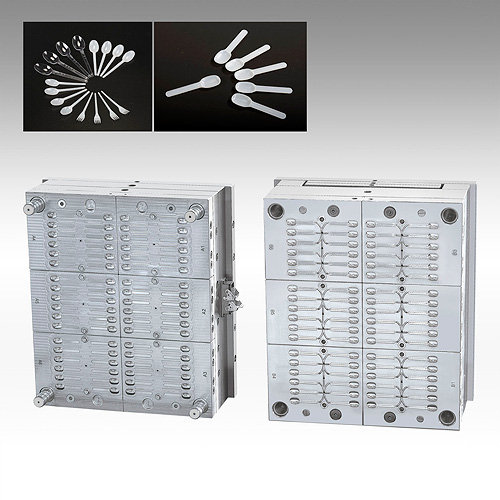

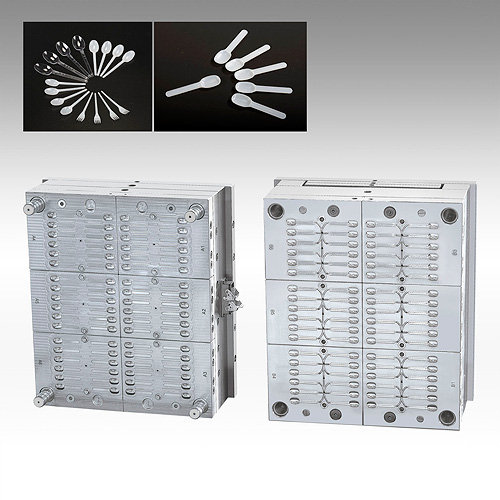

Cutlery Mould(72 cavity)

Technical parameters | Feature | Feature

-

Thin-wall products mould

Technical parameters | Feature | Feature

-

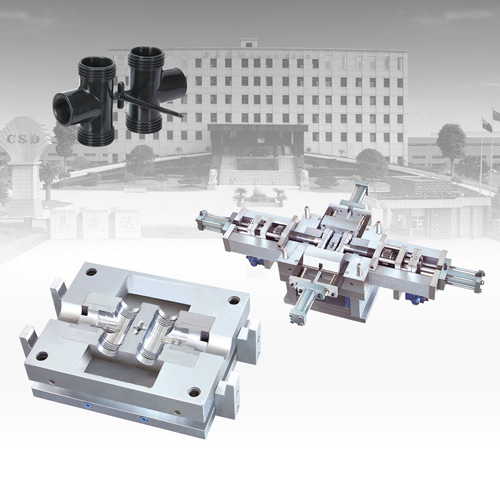

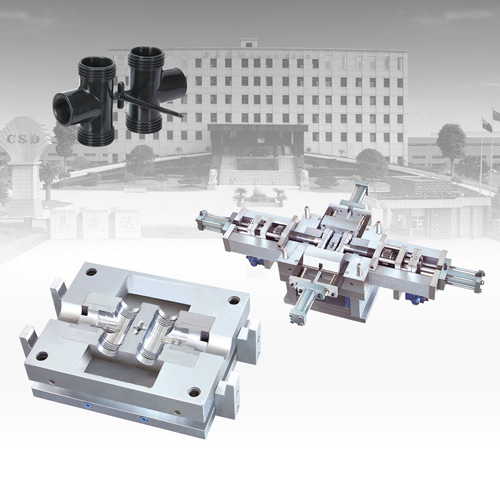

Pipe Fitting Mould

Technical parameters | Feature | Feature

-

Daily Necessities Mould

Technical parameters | Feature | Feature

-

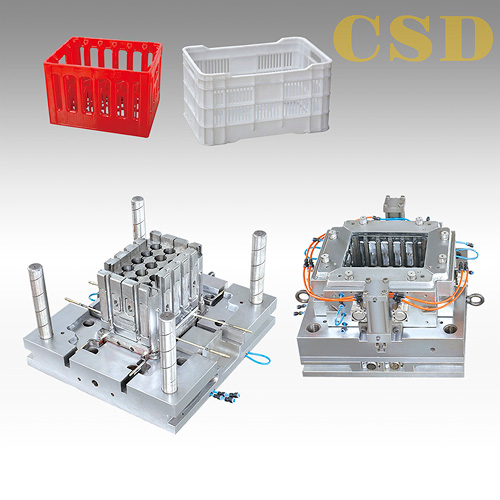

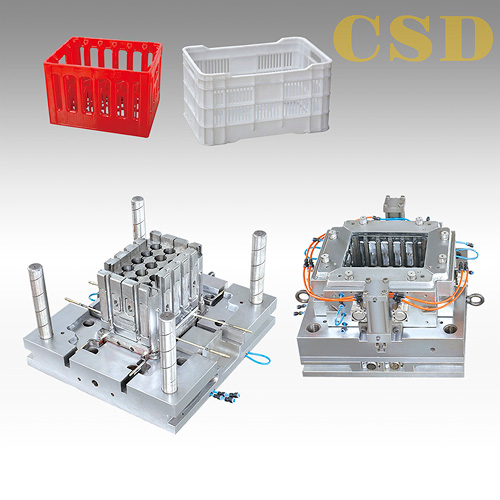

Crate Mould

Technical parameters | Feature | Feature

-

Daily Necessities Mould

Technical parameters | Feature | Feature

-

Blow Mould For 5GL PET bottle

Technical parameters | Feature | Feature

-

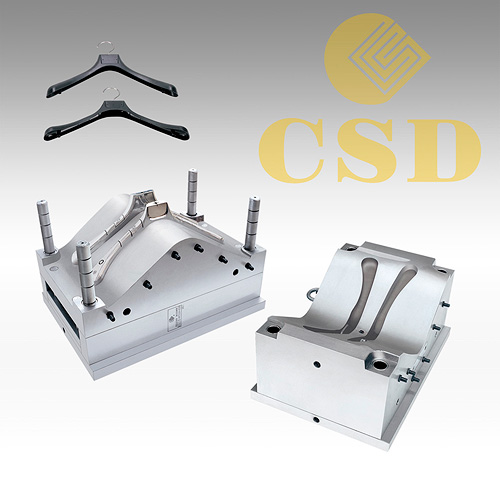

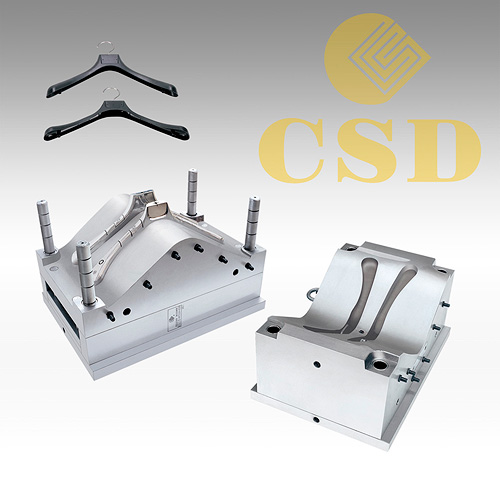

Hanger Mould

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

Technical parameters | Feature | Feature

Technical parameters | Feature | Feature

-

Technical parameters | Feature | Feature

Technical parameters | Feature | Feature

|

|

PRODUCTS PRODUCTS

|

You are here: Home - Products - Injection Molding Machine |

|

| |

|

| Product Name: CSD-550S/X1-20L Injection Molding Machine |

-

1.The optimized elbow bar type high-speed clamping mechanism ensures the ultra-high precision and ultra-long service life of the machine because of the low pressure stress at the joint.

2.Optimize the five-fulcrum clamping mechanism with hyperbolic elbow, which has strong clamping force, fast speed, stable operation, reliable performance and large modulus of volume.

3.After detailed analysis of the template design, the rigidity of the template is greatly improved by using the support continuous casting structure, which not only reduces the deformation of the template, but also reduces the processing difficulty and further reduces the cumulative tolerance.

4.Simple and precise adjusting mechanism of mold thickness ensures enough constant clamping force, which can be adjusted automatically according to clamping tonnage.

5.Efficient injection mechanism: the screw adopts imported materials and then is tightly nitrided to make the screw high-quality and durable, and the reasonable length-diameter ratio makes the plasticization better; the high-precision linear guide rail reduces the movement deviation of the injection process to ensure higher injection accuracy and efficiency.

6.KEBA advanced control interface, high-speed microprocessor, ergonomic layout, direct menu key access, data image monitoring, self-diagnosis and fault detection capabilities.

7.Closed-loop PID temperature control, accurate temperature control, excellent process control stability.

8.Servo motor drive system has fast response, high repetition accuracy, low noise and more energy-saving (30-50% energy-saving compared with conventional machines).

-

| Name of Major Accessories |

Brand |

Origin |

| Servo motor |

Xincheng |

China |

| Servo controller |

Xincheng |

China |

| Gear pump |

Sumitomo |

Japan |

| Hydraulic motor |

Eaton |

Sino-foreign Joint Venture |

| Hydraulic valve |

Vickers /Yuken |

US/Japan |

| Pressure transducer |

Yuken |

Japan |

| Seal ring |

NOK |

Japan |

| Controller |

KEBA |

Austria |

| Contactor |

Schneider |

France |

| Circuit breaker |

Schneider |

France |

| Travel switch |

Omron |

Japan |

| Proximity switch |

Omron |

Japan |

| Displacement sensor |

NOVOtechnik |

Germany |

|

|

|