-

FG Series High Precision & Direct Pressure Injection Molding Machine(80-250T)

Technical parameters | Feature | Feature

-

CSD-LINE-L12B4 Injection Molding Machine

Technical parameters | Feature | Feature

-

CSD-PET-DP Series High Precision,High Capacity Direct Pressure PET Production Line

Technical parameters | Feature | Feature

-

CSD-RP 10-20 Cavity High Precision High-speed Rotary Blowing Machine

Technical parameters | Feature | Feature

-

CSD-PET-DP Series High Precision,High Capacity Direct Pressure PET Production Line

Technical parameters | Feature | Feature

-

CSD-550S/X1-20L Injection Molding Machine

Technical parameters | Feature | Feature

-

FG Series High Precision & Direct Pressure Injection Molding Machine(80-250T)

Technical parameters | Feature | Feature

-

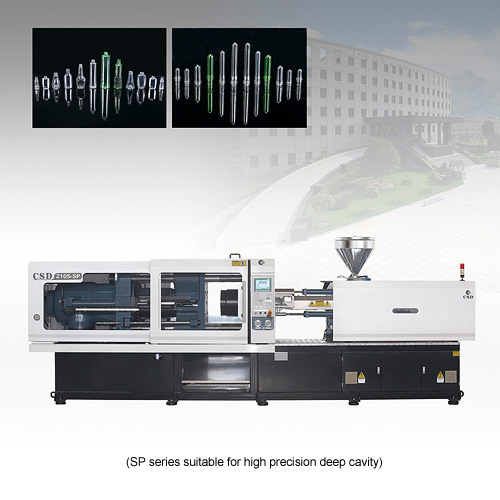

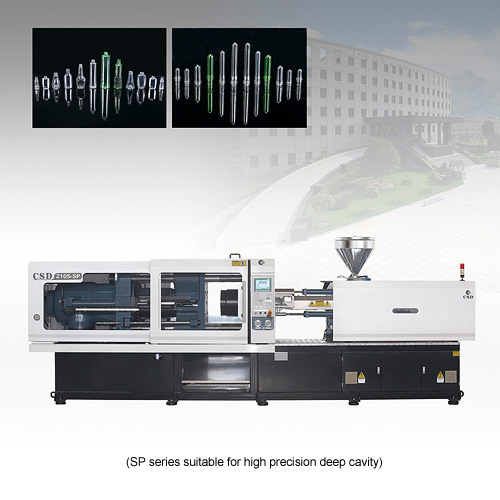

SP Series High Precision & Direct Pressure Injection Molding Machine(80-250T)

Technical parameters | Feature | Feature

-

P Series Injection Molding Machine(150-680T)

Technical parameters | Feature | Feature

-

W-S Series Injection Molding Machine(100T-280T)

Technical parameters | Feature | Feature

-

W-S Series Injection Molding Machine(350T-1200T)

Technical parameters | Feature | Feature

-

S Series Injection Molding Machine(260T-320T)

Technical parameters | Feature | Feature

-

CSD-RP 10-20 Cavity High Precision High-speed Rotary Blowing Machine

Technical parameters | Feature | Feature

-

AB Up Blow Series Automatic Blow Molding Machine(2 Cavity,4 Cavity,Maximum Capacity:2 Liter)

Technical parameters | Feature | Feature

-

AB Up Blow Series Automatic Blow Molding Machine(6 Cavity,8 Cavity,Maximum Capacity:1.5 Liter)

Technical parameters | Feature | Feature

-

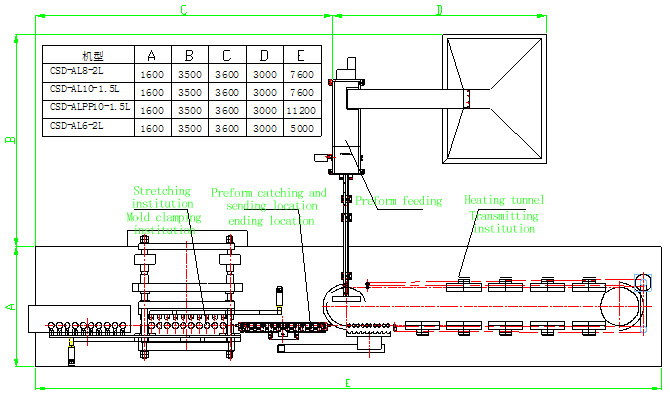

PET Two-Stage Automatic Linear High-Speed Blow Molding Machine(10 Cavity,12 Cavity,Maximum Capacity:1.5 Liter)

Technical parameters | Feature | Feature

-

PET Two-Stage Linear High-Speed Automatic Blow Molding Machine

Technical parameters | Feature | Feature

-

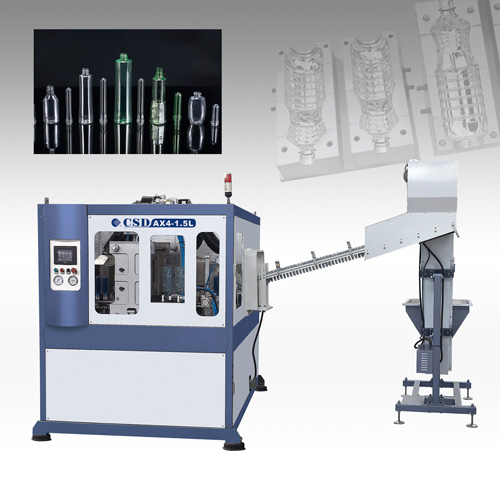

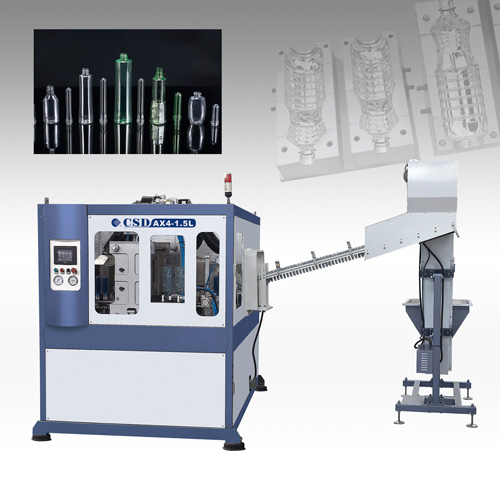

AX Down Blow Series Automatic Blow Molding Machine(1,2,3,4,6 Cavity,Maximum Capacity:1.5 Liter)

Technical parameters | Feature | Feature

-

1 Cavity Manual Preform Feeding Maximum Capacity:2Liter Long message 2/3 ter

Technical parameters | Feature | Feature

-

AX Down Blow Series Automatic Blow Molding Machine(1,2,3,4,6 Cavity,Maximum Capacity: 1.5 Liter)

Technical parameters | Feature | Feature

-

AX Down Blow Series Automatic Blow Molding Machine(1 Cavity,2 Cavity,Maximum Capacity:5 Liter)

Technical parameters | Feature | Feature

-

1 Cavity Manual Preform Message 3/3 form Feeding.Maximum Capacity:5 Liter

Technical parameters | Feature | Feature

-

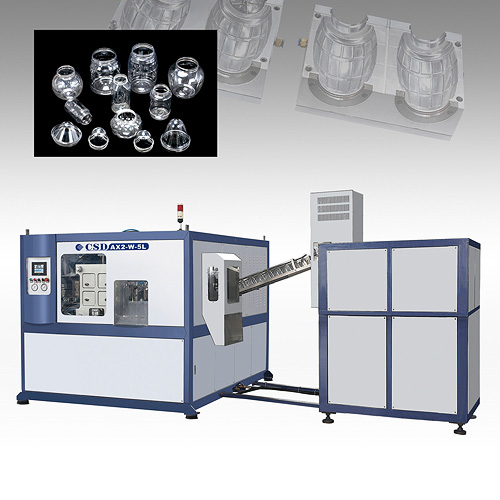

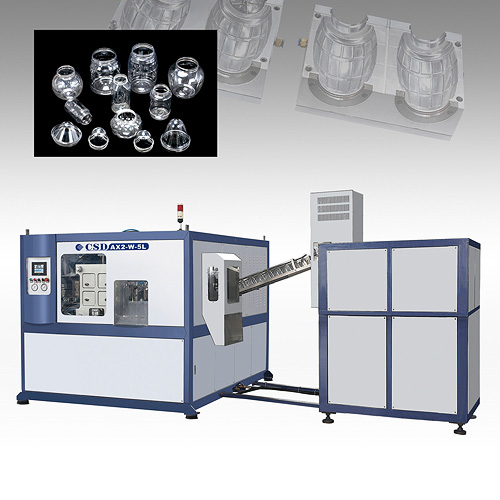

AX Down Blow Series Automatic Blow Molding Machine(1 Cavity,2 Cavity,Wide Mouth Jar, Maximum Capacity:5 Liter)

Technical parameters | Feature | Feature

-

Semi-Automatic Blow Molding Machine

Technical parameters | Feature | Feature

-

Semi-automatic Blow Molding Machine

Technical parameters | Feature | Feature

-

Semi-Automatic Blow Molding Machine

Technical parameters | Feature | Feature

-

PET 5-Gallon Automatic Blow Molding Machine(1 Cavity,Preform Feeding by Hand)

Technical parameters | Feature | Feature

-

PET 5-Gallon Semi-Automatic Blow Molding Machine(1 Cavity)

Technical parameters | Feature | Feature

-

PC 5-Gallon Blow Molding Machine(1 Cavity)

Technical parameters | Feature | Feature

-

EB Series Extrusion Blow Molding Machine(Double Station,Multi-heads,Screw Diameter:45mm,55mm,65mm,75mm)

Technical parameters | Feature | Feature

-

EBS Servo Drive Series Extrusion Blow Molding Machine(Double Station,Multi-heads,Screw Diameter:50mm,60mm,70mm,80mm)

Technical parameters | Feature | Feature

-

EB Series Extrusion Blow Molding Machine(Double Station,Multi-heads,Screw Diameter:80mm,90mm,100mm)

Technical parameters | Feature | Feature

-

EB Series Extrusion Blow Molding Machine(Single Station,Screw Diameter:90mm,100mm)

Technical parameters | Feature | Feature

-

Preform Mould With Hot Runner Valve Gate

Technical parameters | Feature | Feature

-

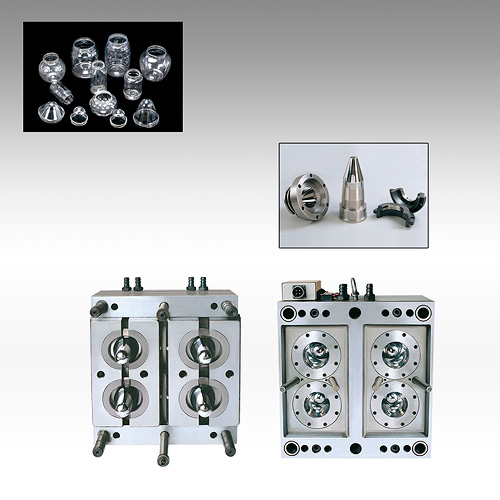

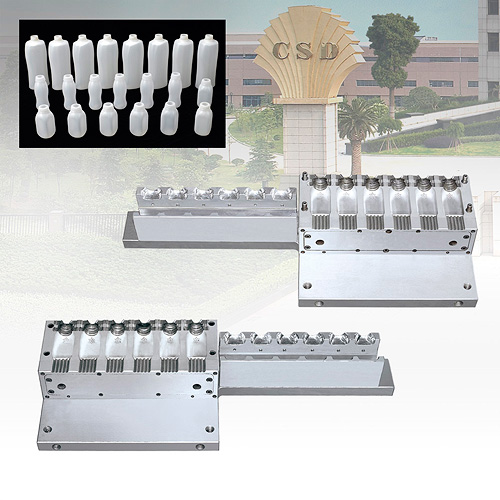

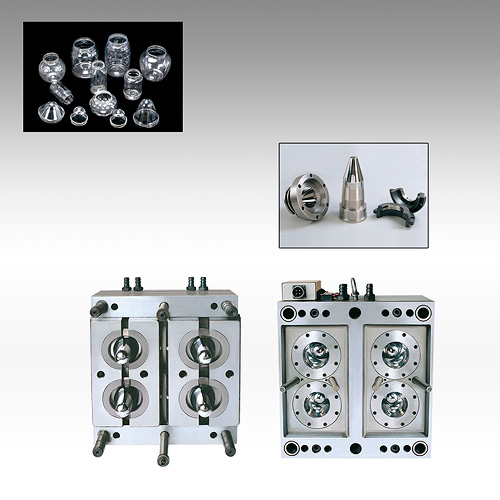

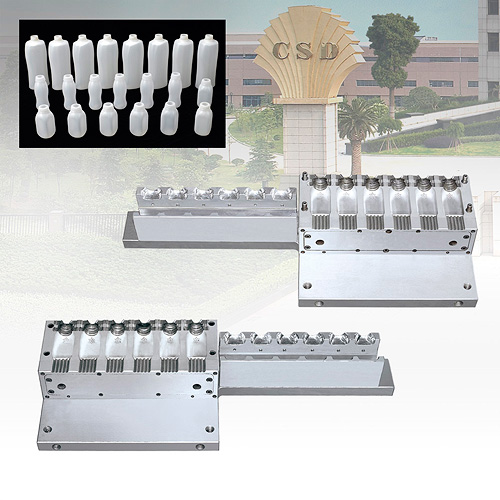

Jar Preform Mould

Technical parameters | Feature | Feature

-

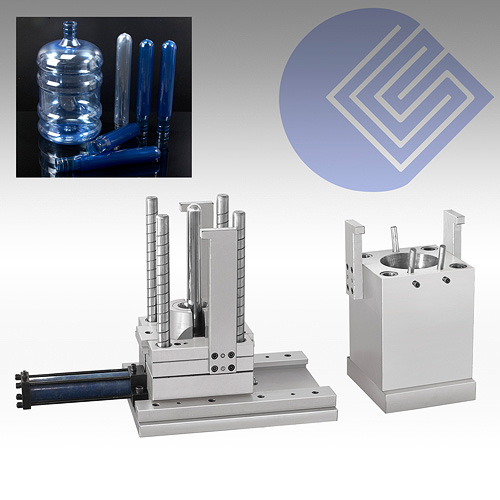

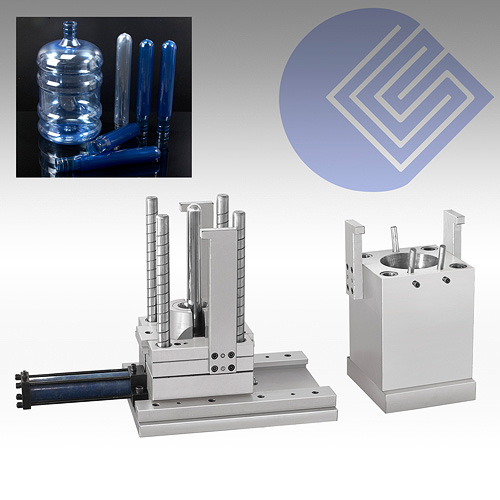

1 Cavity 5 Gallon Preform Mould

Technical parameters | Feature | Feature

-

Anti-proof Cap Mould with Hot Runner

Technical parameters | Feature | Feature

-

Blow Mould for PET Bottle(6 Cavity)

Technical parameters | Feature | Feature

-

Blow Mould for Extrusion Blow Molding Machine(6 Cavity)

Technical parameters | Feature | Feature

-

PC 5-Gallon Blow Mould

Technical parameters | Feature | Feature

-

Blow Mould for Extrusion Blow Molding Machine(2 Cavity)

Technical parameters | Feature | Feature

-

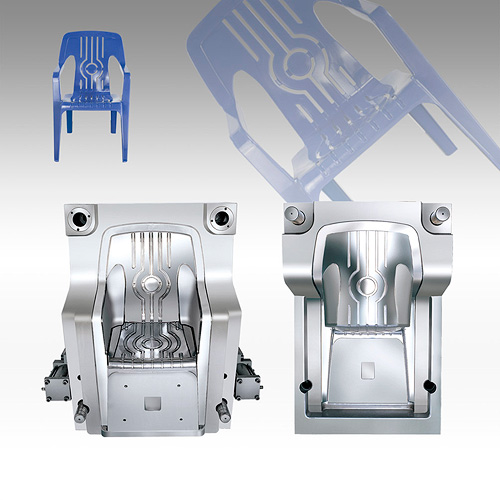

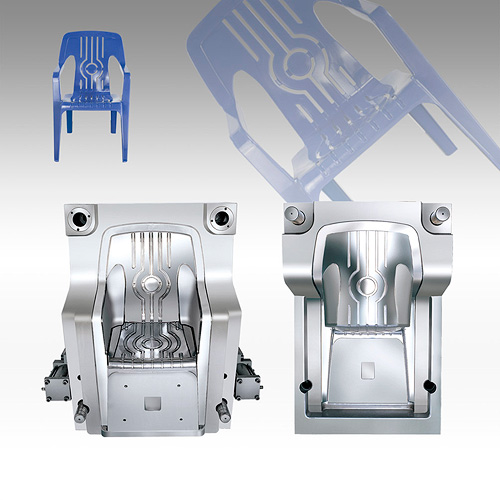

Plastic Chair Mould

Technical parameters | Feature | Feature

-

Blow Mould for PET Bottle(1 Cavity)

Technical parameters | Feature | Feature

-

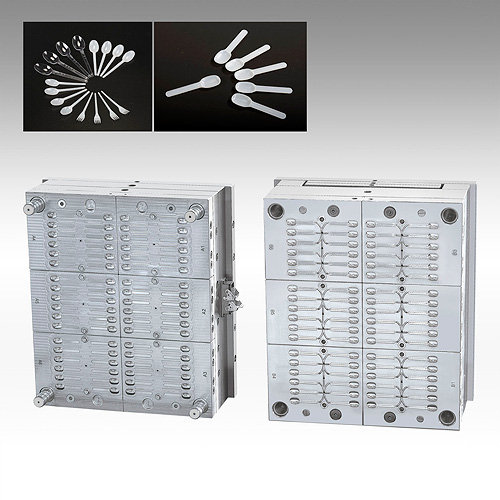

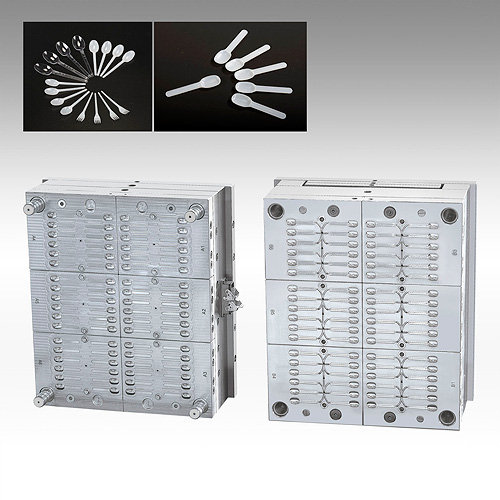

Cutlery Mould(72 cavity)

Technical parameters | Feature | Feature

-

Thin-wall products mould

Technical parameters | Feature | Feature

-

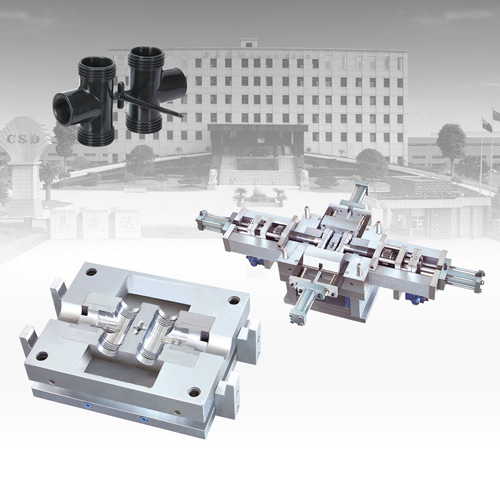

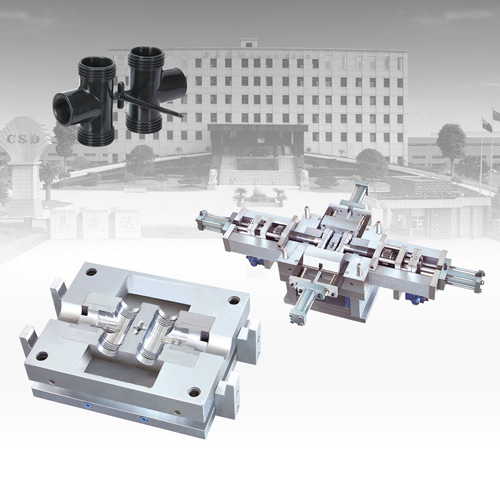

Pipe Fitting Mould

Technical parameters | Feature | Feature

-

Daily Necessities Mould

Technical parameters | Feature | Feature

-

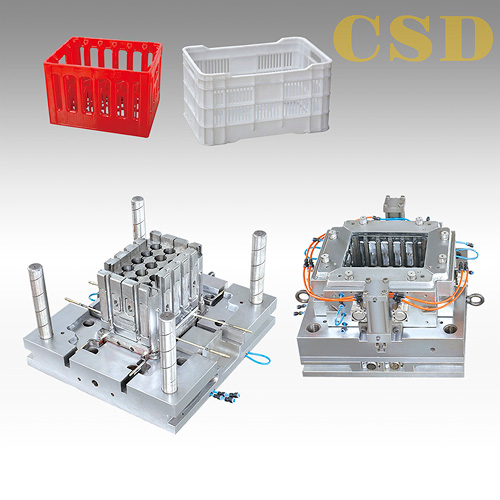

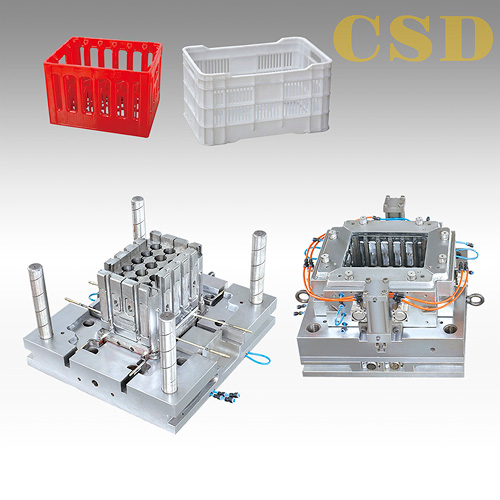

Crate Mould

Technical parameters | Feature | Feature

-

Daily Necessities Mould

Technical parameters | Feature | Feature

-

Blow Mould For 5GL PET bottle

Technical parameters | Feature | Feature

-

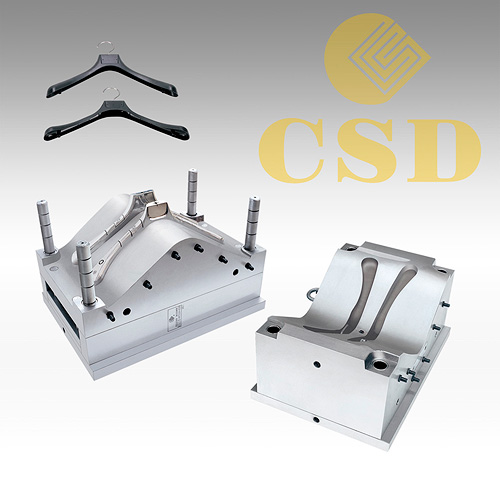

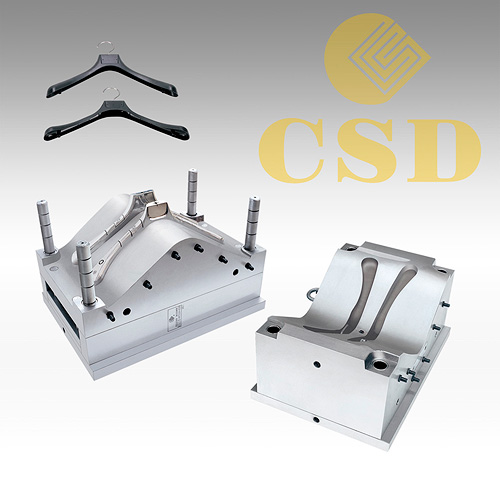

Hanger Mould

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

PET Preform

Technical parameters | Feature | Feature

-

Technical parameters | Feature | Feature

Technical parameters | Feature | Feature

-

Technical parameters | Feature | Feature

Technical parameters | Feature | Feature

|

|

PRODUCTS PRODUCTS

|

You are here: Home - Products - PET Two-Stage Blow Molding Machine |

|

| |

|

| Product Name: PET Two-Stage Automatic Linear High-Speed Blow Molding Machine(10 Cavity,12 Cavity,Maximum Capacity:1.5 Liter) |

-

1. Vertical rotated continuous preform feeding device of inventional patent design, feeding preform precisely and rapidly. No preform drop and get stuck.

2. Pressure charged toggle mold clamping system of patent design lock the mold firmly;

3. Servo control stretching and location, time and speed adjustment according to the needs, improving product quality.

4. Servo cylinders feed and unscramble preforms, take bottles rapidly and accurately;

5. Imported PLC automation control enable non-stop machine parameter adjustment.

-

1.World famous brand pneumatic components;

2.World famous brand electrical components.

|

|

|